Product Details-

ARES FURNACE

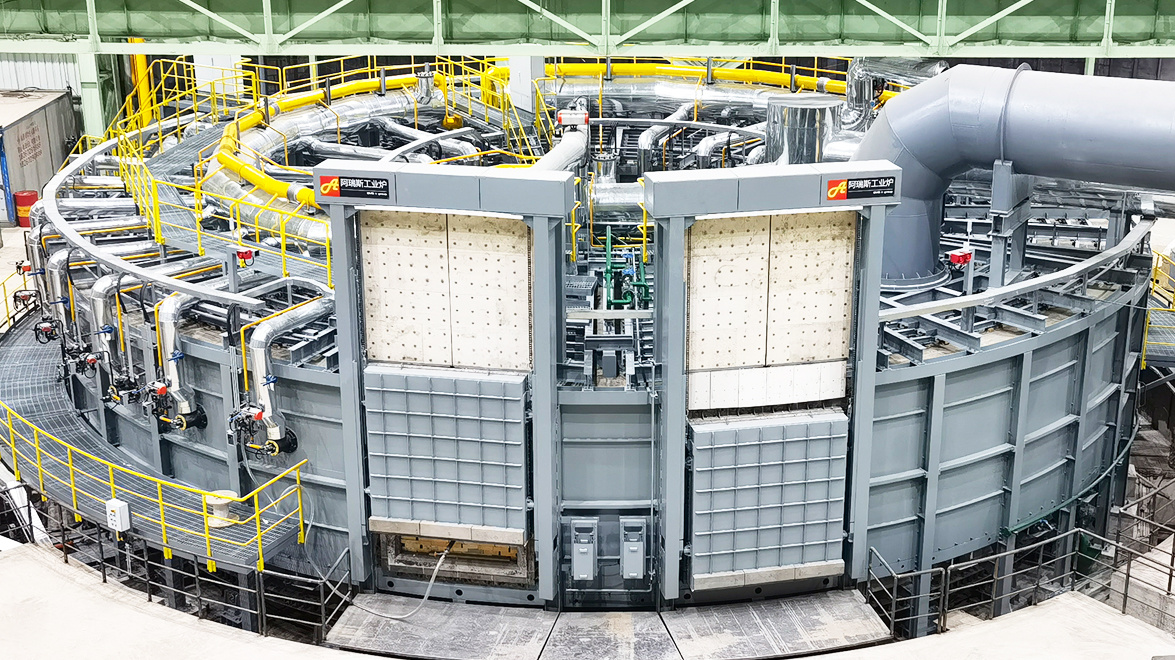

ROLLER HEARTH FURNACE FOR CrNi STEEL TUBES UNDER H2

TRF-H series heat treatment line is designed by ARES for various heat treatment processes such as bright solid solution and softening annealing of CrNi steel tubes. It adopts a 100% hydrogen protection atmosphere and a pulse-controlled recuperative burner system equipped with Si-SiC radiation tubes for indirect heating. The tube is evenly heated and cooled during the heat treatment process, whose surface is bright and oxidation-free after the treatment. The maximum furnace temperature of the TRF-H heat treatment line can reach up to 1180 ℃, and the cooling rate of thin-walled tubes can reach 300 ℃/min thanks to ARES patented technology JCU (Jet Cooling Unit).

ARES Intelligent Control System has been applied to BRF series heat treatment lines, which has been equipped with Heat Treatment Line Remote Service System (RDMS), Industrial Furnace Production Data Intelligent Analysis System (FDAS). The use of the above technologies can greatly improve the stability of product quality, enhance equipment efficiency, and reduce production costs.

Material:Stainless steel

Product shape:Cold milling tubes,Welded tube

Product size:Φ5-50 x 0.5-6.0 x 3,000-36,000 mm

Treatment process:Solution, annealing

Surface quality:Bright, non- oxidation

Maximum temperature:1,180 ℃

Fuel:NG, Mix gas, Electricity

Protective atmosphere:H2

Capacity:0.8 ~5.0 t/h

Key words:

ROLLER HEARTH FURNACE FOR CrNi STEEL TUBES UNDER H2

Classification:

Tube & Pipe

Previous Page

Related Product

Immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!