Product Details-

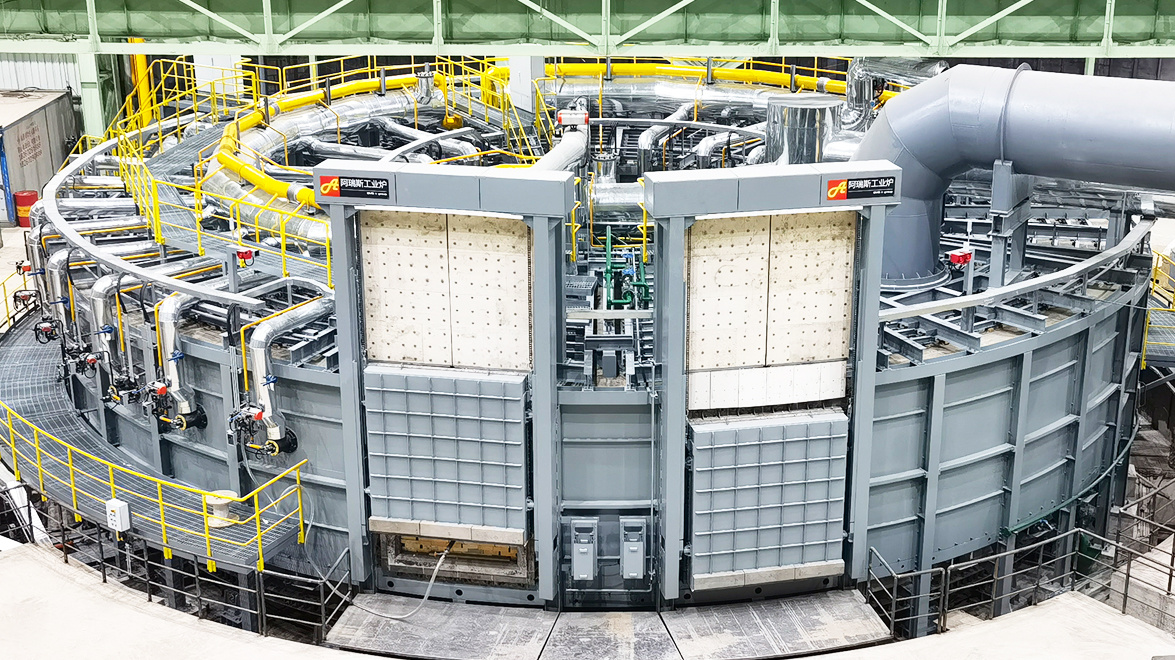

ARES FURNACE

ARES HEAT-TREATMENT TECHNOLOGIES FOR SILICON STEEL STRIPS

Decarbonizing Annealing Line (DCL): Cold-rolled strip steel is heated to the annealing temperature in a radiant tube furnace (RTF), slowly cooled to 600 ℃ with a cooling rate controlled at 10 ℃/sec at first, and then rapidly cooled below 100 ℃. The atmosphere inside the furnace is hydrogen (up to 75%) and nitrogen, and the protective atmosphere can be humidified, or a proper amount of ammonia gas can be introduced to achieve decarburization or nitridation of the strip steel. After annealing, the surface of the steel strip will be coated with MgO, and finally, the coating will be dried and cooled to the ambient temperature.

Final Hot-stretching and Flattening Line (FCL):

After being coated with insulation coating, the strip steel is heated to around 700 ℃ by an open flame, then it proceeds into the radiation tube (RTF) and is heated to the process temperature, holding for a period of time. After that, the workpiece is slowly cooled to 600 ℃ with a cooling rate controlled at 10 ℃/sec and then rapidly cooled below 300 ℃. In this section of the furnace, nitrogen and hydrogen are used as protective atmospheres in the RTF. Finally, the strip steel is cooled to 80 ℃ using air jet cooling (AJC) after having been discharged from the furnace.

Annealing Line for Non-oriented Silicon Steels (ACL):

Cold-rolled steel strips are heated to the annealing temperature through a radiant tube furnace (RTF) or an open flame non-oxidation heating furnace and are uniformly heated for a certain period of time. The atmosphere inside the furnace is hydrogen and nitrogen, or a humid atmosphere is added to control the degree of decarbonization. After that, strips are slowly cooled to 600 ℃ at the beginning and then quickly cooled to 80 ℃. After annealing, the surface of steel strips will be coated with insulation coatings which will be dried and sintered afterwards.

Oriented Silicon Decarbonizing Line

Material:CGO / Hi-B

Product size:Width:500~1300, thickness:0.15~0.5mm

Heat-treatment process:Decarbonizing、Nitriding、MgO Coating drying

Maximum temperature:1050°C

Atmosphere gas:N2/H2、N2/H2/NH3

Process speed:35-120 m/min

Oriented Silicon Strip Final Coating and Hot Stretching & Flattening line

Material:CGO / Hi-B

Product size:Width:500~1300, thickness:0.15~0.35mm

Heat-treatment process:Coating drying, Hot stretching and flattening

Maximum temperature:1000℃

Atmosphere gas:N2 / H2

Process speed:50-130 m/min

Non-Oriented Silicon Strip Annealing line

Material:High-B,High&Middle&Low grade

Product size:Width:500~1300, thickness:0.15~0.65mm

Heat-treatment process:Annealing, Decarbonizing、Drying and Sinter

Maximum temperature:1100℃

Atmosphere gas:N2 / H2

Process speed:35-200 m/min

Key words:

ARES HEAT-TREATMENT TECHNOLOGIES FOR SILICON STEEL STRIPS

Classification:

Silicon steel

Related Product

Immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!