Product Details-

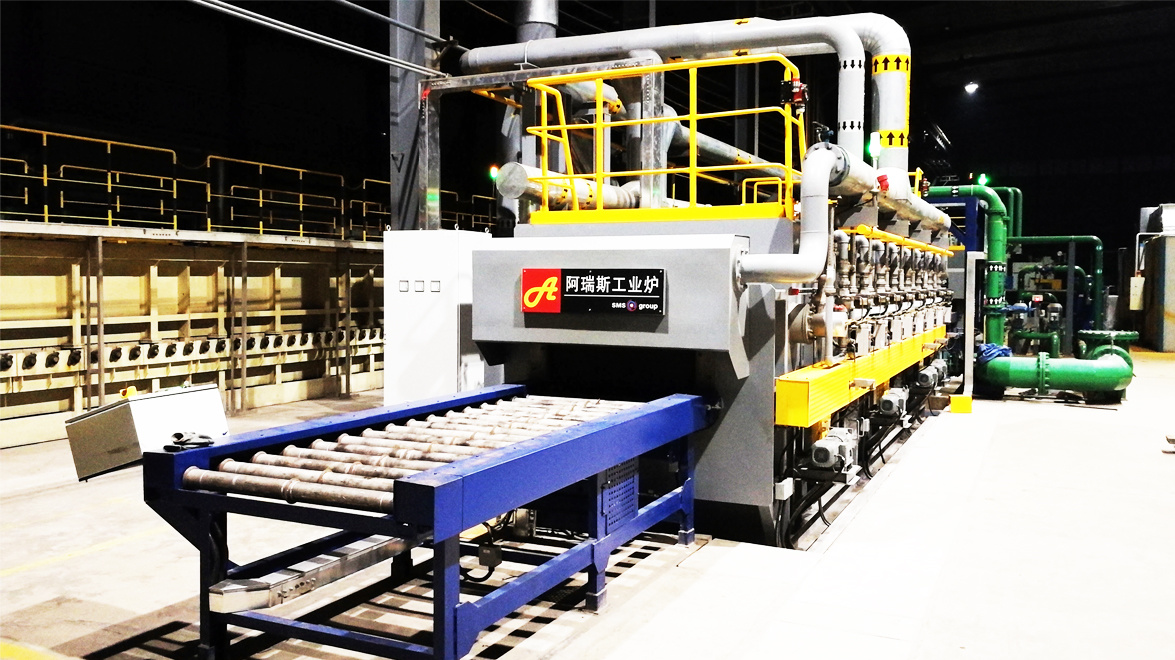

ARES FURNACE

ROTARY HEARTH FURNACE

ARES RHF rotary hearth furnace is suitable for heating of pipe billets, castings, and forgings, heat treatment of coils, wheels, castings, forgings, and silicon steels, as well as high-temperature reduction of direct-reduced iron, whose maximum furnace temperature can reach up to 1400 ℃. It is an essential heat treatment furnace for enterprises engaged in rolled steels, high-end castings and forgings, and special heat treatment production.

Features of RHF

A double-deck fan-shaped furnace bottom frame structure is adopted to effectively reduce the high temperature external expansion from the furnace bottom and to ensure long-term stable operation of the equipment.

The patented support rollers, centering rollers, and transmission devices ensure smooth operation of the furnace bottom and highly accurate positioning of materials inside the furnace.

The optimized design of refractory materials for the furnace body can effectively prevent the high temperature external expansion from the furnace hearth, the lower temperature of the furnace wall and top, and reduce energy consumption significantly.

Hydraulic motor drive enables high torque to be achieved. Multiple motors running synchronously, combined with a material tracking system, positioning of materials in the furnace is more precise.

A new high-temperature flameless combustion system has been adopted to achieve low NOX emissions, meeting environmental requirements.

The degree of automation is so high that the entire process of charging and discharging and the control of the combustion system can be completed automatically without manual intervention.

ARES Remote Service System (RDMS) and Industrial Furnace Production Data Intelligent Analysis System (FDAS) can be configured, which can greatly improve the stability of product quality, enhance the production efficiency in connection with the previous and next production processes, and reduce production costs usefully.

Product shape:Billet heating, casting / forging heating and heat treatment, coil / wheel / silicon steel heat treatment, direct reduction iron

Average diameter:Φ2~50m

Capacity:5~250t/h

Max. temperature:450~1400℃

Atmosphere:Open fired / Protective gas

Fuel:NG, Mix gas, Electricity

Corollary equipment:Charge and discharge machine

Key words:

ROTARY HEARTH FURNACE

Classification:

加热炉

Related Product

Immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!